Why Chip Shortages Still Impact U.S. Car Buyers in 2025

Even in mid-2025, automakers in the U.S. are scrambling for mature-node chips (28 nm/40 nm) that power safety cameras, infotainment screens, and hybrid systems. Many U.S. factories can’t get enough of these parts to build fully equipped vehicles. The result for you? Cars that roll off the lot without key features—then sit in dealer yards until the “free retrofit” parts arrive weeks or months later.

What Features Are Missing From New Vehicles

- ADAS cameras and radar modules (lane-keep, blind-spot, adaptive cruise).

- Infotainment processors and digital-cluster ICs (touchscreens, digital gauges).

- Hybrid inverter and power-management chips (unique to hybrid/EV models).

Because most U.S. automakers delayed new fab investments until 2027+, tight supplies remain the norm.

Placeholder Vehicles Come With Surprise Costs

When electronics aren’t available at assembly, U.S. dealers often deliver “placeholder” vehicles:

Blank or Disabled Panels at Delivery

- You drive home with dark instrument clusters or taped-off camera housings.

- Critical safety functions (blind-spot monitoring, adaptive cruise) aren’t active until parts arrive.

Sticker Shock & Unexpected Charges

- Features that were once standard are now “optional.” If you skip an upgrade, you might think you’re saving money, only to find out later you have to pay $1,000–$3,000 for a retrofit or wait indefinitely.

- Some U.S. dealers levy “placeholder” or “expediting” fees ($500–$2,000) for ordering scarce modules without guaranteeing a firm delivery date.

Toyota Avoids Delays With Smarter Chip Strategy

According to a May 2025 Toyota press release, the company pre-ordered large quantities of critical chips for its U.S. plants. As a result, Camry Hybrid (2025) carries a 0-day wait for fully installed ADAS, digital dash, and infotainment. As a result, if you need a fully loaded, drive-away-ready hybrid today, Toyota’s U.S. stockpile strategy keeps you clear of blank screens and taped-over sensors.

Smart Shopping Tips For New Car Buyers

- Demand Written Delivery Commitments for Each Feature

Example: “Blind-spot camera module must arrive by July 15,” or “Digital gauge retrofit scheduled by August 1.”If a dealer only offers “we’ll let you know,” treat it as a red flag and consider another dealership or brand.

- Inspect In-Stock Cars Thoroughly

Even if a dealer claims to “have ID.4s on the lot,” confirm every must-have feature (backup camera, touchscreen nav, adaptive cruise) is active. If any cameras are taped or screens read “System Inactive,” demand a precise retrofit date before you sign. - Be Flexible on Color or Minor Options

Forego a premium paint or special wheel package to cut weeks off your wait. Dealers often have baseline inventory; skipping non-essential options can get you a complete vehicle sooner. - Watch for Hidden “Placeholder” Fees

- According to CarEdge, many U.S. dealers deliver “placeholder” builds with taped-off camera housings, inactive instrument clusters, or deactivated infotainment; buyers drive home without blind-spot reminders, digital gauges, or connected-car features—then wait for a “free retrofit.

- ”Prioritize Brands with Proven Supply Buffers

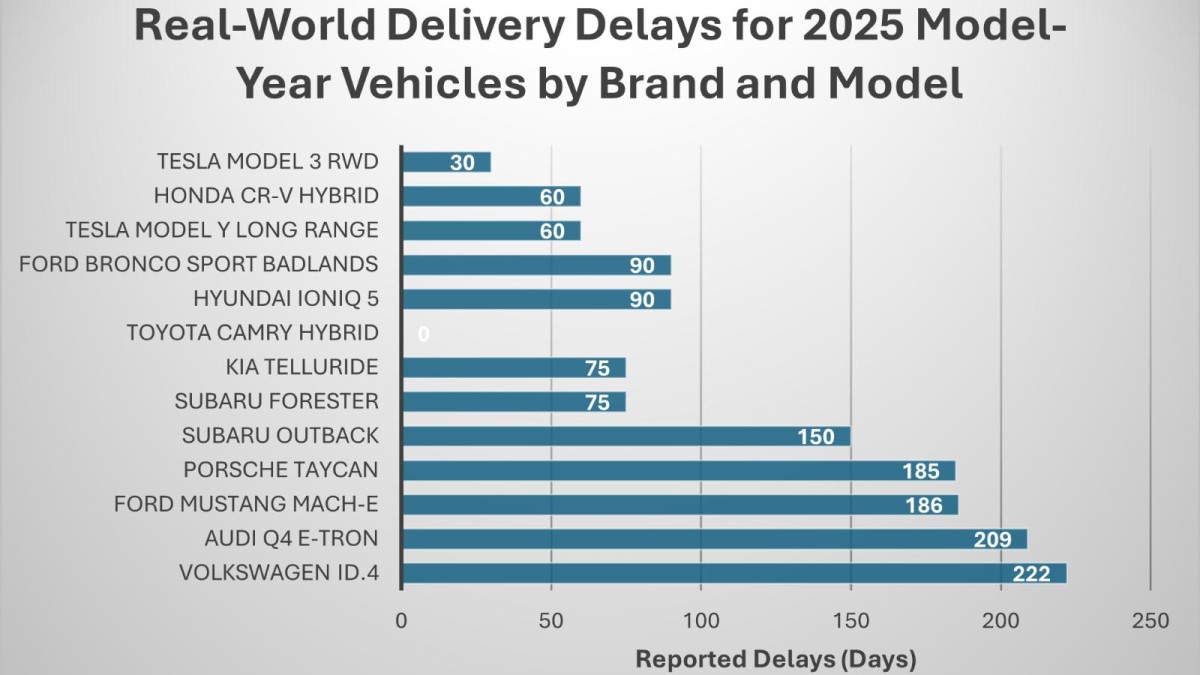

- According to Edmunds’ recent delivery‐tracking data, Toyota and Tesla (for base Model 3/Model Y) remain the most reliable bets in the U.S. They consistently deliver fully equipped cars—Toyota via its chip stockpile and Tesla via vertical integration.

Bottom Line: Protect Yourself

For U.S. buyers, “order-now, drive-later” remains a reality for many 2024–2025 models. You may face blank dashboards, disabled safety functions, and surprise retrofit fees. Protect yourself by insisting on written feature-by-feature delivery dates, inspecting any “in-stock” vehicle for missing components, and prioritizing automakers (like Toyota and Tesla) that secured their chip supply early. That way, you’ll avoid hidden costs and months of frustration before finally getting every safety and infotainment feature you paid for.